Some more soldering

Some more soldering

You’ve passed the worst part. Just a couple of components more and we’re done… this will be a piece of cake.

Step 13 – solder the second 10k ohm resistor

This resistor is important for connecting the microcontroller to the serial UART programmer board.

It’s labeled R3 and the color code goes brown, black, black, red, brown.

Step 14 – female 6-pin angle header

Locate this black female connector.

It’s soldered to the place labeled “JP2, serial programmer”.

The serial UART programmer board is connected to this port.

Make sure to turn it the right way.

Pro tip: If the component is falling out of the PCB when you try to solder it, place your cutting pliers’ handle underneath the component you’re soldering.

Step 15 – two wheel potentiometers

Now we’ll locate and solder the two trim potentiometers labeled TR1 & TR2.

The left potentiometer is used for regulating the screen’s backlight and the right one regulates the sound volume.

Make sure to use our previous pro tip here and put your pliers underneath the potentiometers while soldering them.

Step 16 – 3×2 ICSP header & 100nF capacitors

The header is mounted on the top left front side of the PCB (labeled JP1). After the header, find the two little 100nF capacitors (they have 104 written on their surface) and solder them on places labeled with C1 and C6.

Step 17 – some more resistors and a diode

Ok, let’s solder the rest of the small two-leaded components.

- Solder the 2.2k ohm resistor (red, red, red, golden) to the place marked “R1, 2k”

- 100 ohm resistor (brown, black, brown, golden OR brown, black, black, black, brown) to the spot marked “R6, 100”

- two 4.7k ohm resistors (yellow, purple, red, golden) need to be placed on the marking “R4, 4k7” and “R5, 4k7”

- 1N4148 diode needs to go where “D1, 1N4148” is written on the board.

Important: mind the polarity of the diode by making sure that the black ring on the diode matches the marking on the PCB

Step 18 – headphone connector

The headphone connector goes to the place marked“X1, STEREOJACK”.

Although this connector was built for stereo sound output, MAKERbuino can only output bleeps and bloops in mono. Because of that, both left and right earphone are bridged together and connected to the same sound output channel on the microcomputer.

Make use of our previous pro tip and place your pliers beneath the connector so that it doesn’t fall off while you’re soldering it.

Step 19 – Li-Po charger board

For mounting the TP4056 Li-Po charger board, you’ll need to make use of those tiny excess cut-off leads we’ve told you to save on step 3.

Pick four of the longest leads from the pile of excess leads and insert them through charger’s and PCB’s contacts and bend them before soldering.

You need to solder the contacts both on the top and the bottom side of your MAKERbuino in order for the charger to work properly.

Electronics 101: This way of adding stack-on PCBs to the main PCB is called the “child board design”. Boards stacked onto the main PCB are called the “child boards”.

Step 20 – male 4-pin angle multiplayer headers

These are labeled as JP3 and JP4 on the board. Use the pro tip about placing the pliers underneath the component because these might be a bit harder to solder.

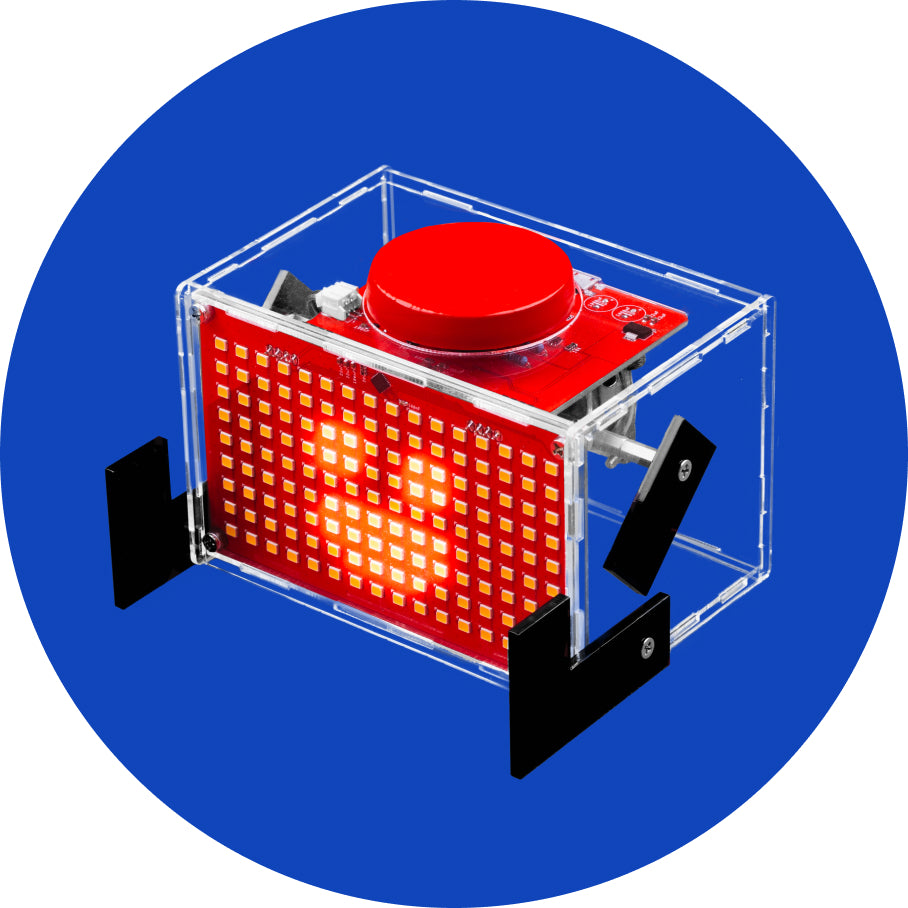

Step 21 – seven big clicky pushbuttons

Finally! Time’s to solder the yellow pushbuttons.

Important: make sure to push the pushbuttons all the way down to the PCB, otherwise they might get angled, which will cause them to jam when you mount the front casing.